Case Study

Loch Electronics Ltd

Partners

Robert Gordon University

Sectors

Engineering and Technology

Regions

Glasgow & Clyde Valley

Background

Loch Electronics innovate, engineer, design and bring to market consumer electronics products focused on reducing global carbon footprint in households and offices.

Conventional dishwashers are incompatible with the most common household sizes in the UK; they are too big. Loch Electronics has been developing a concept dishwasher design, suitable for small households. In their design, the water spray system was modified to take less space and increase water flow directed at the dishes. As a result, the design is anticipated to offer increased process efficiency, reduced operational time and energy usage.

Challenge

To prove their concept, the company was looking to collaborate with an academic partner with expertise in fluid dynamics.

Solution

Referred by Business Gateway, Interface was able to successfully match Loch Electronics to the academic team at Robert Gordon University (RGU). The team has considerable expertise in fluid dynamics and thermo-fluids, with years of experience working on a wide variety of collaborative research studies on the performance evaluation of complex flow handling systems; leading to optimal designs and enhanced operational efficiencies.

Funded by a Scottish Funding Council (SFC) Standard Innovation Voucher, the project involved detailed investigation into the performance characteristics of the dishwasher.

The primary outcome of this project was the hydrodynamic characterisation of the concept dishwasher design. This involved detailed investigation into the performance characteristics of the dishwasher. A systematic parametric investigation was carried out to achieve this. This scientific research will enable the company to develop and market these dishwashers with enhanced knowledge of its working; allowing prototypes to be built for real world testing and analysis, leading to further developments.

Benefits

The innovative water spray system will result in a compact dishwasher design, ideally suited for small households. In this concept dishwasher design, the water spray system was modified to take less space and increase water flow directed at the dishes. This innovation results in enhanced process efficiency, reduced operational time and energy usage, higher power and cost savings, and lower carbon footprint of the device. It is therefore a very saleable product, easy to store and maintain, and with a low cost to manufacture and ship.

Follow-on Activity

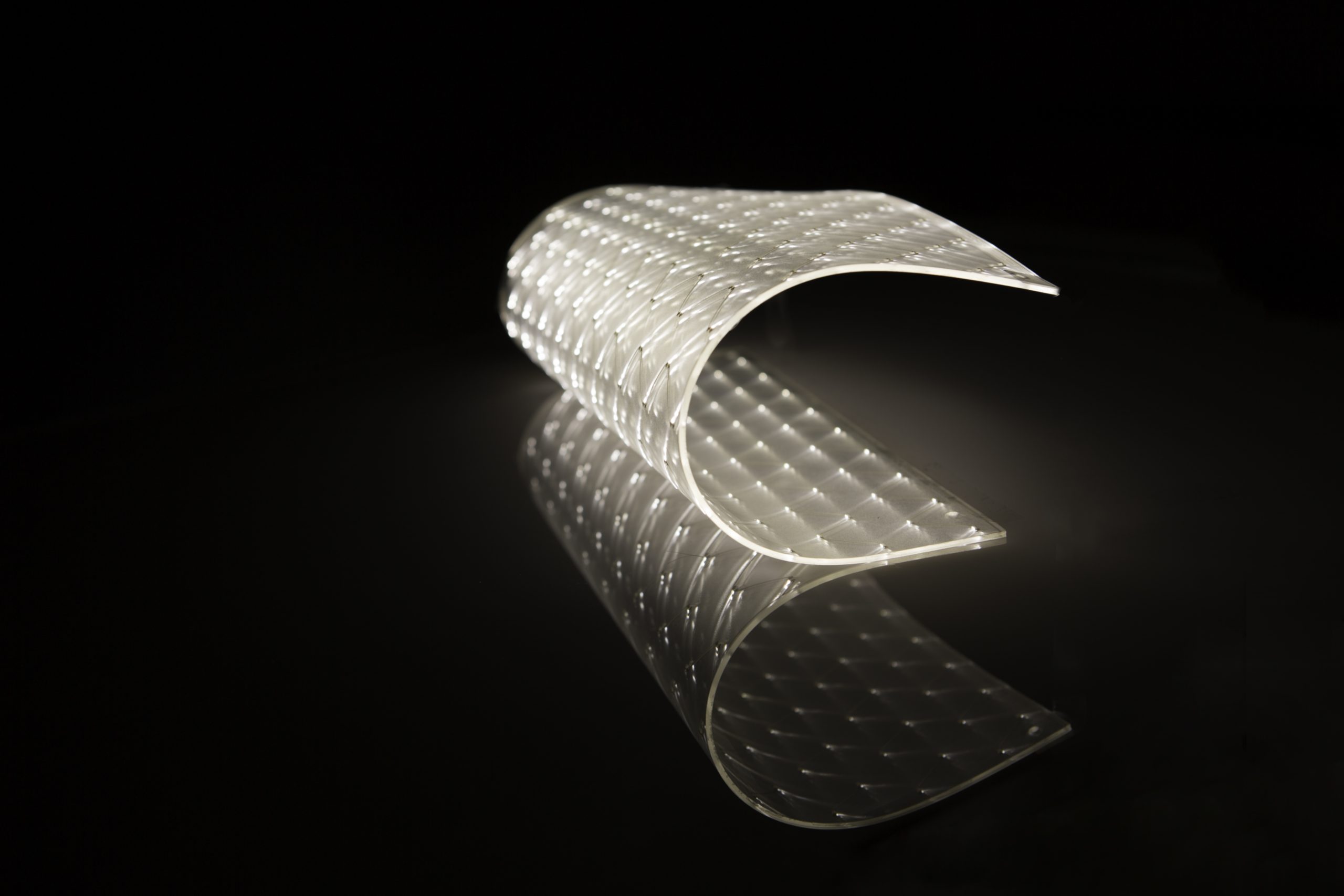

After successful completion of the initial collaborative project, both Loch Electronics and RGU wanted to collaborate further on the capsule dishwasher, specifically on the integration of UV lights, to enhance its capabilities through the inclusion of sanitisation and disinfection functions for protection against COVID-19.

Laboratory tests carried out by an American working group on COVID-19 show that the virus can remain infectious for up to 2-3 days on stainless steel and plastics. UVC (Ultraviolet type C) lights have long been used for sanitation and disinfection purposes and a recent study in the American Journal of Infection Control found that UVC light exposure completely inactivated the virus in 9 minutes.

A SFC Advanced Innovation Voucher was awarded to create prototypes and carry out testing to prove the theory in practice.

Benefits

With precise control of the amount of exposure to the UVC lights, many different items made of different materials could be disinfected of any bacteria and viruses, limiting the spread of COVID-19. As dishwashers are used in 49% of the households across the UK, and 45% of households across Europe, the impact of this UVC integrated dishwasher would be substantial in helping to stop the spread of COVID-19 and any future viruses as well. As the dishwasher will be compact, it will be ideal for use in small households, nursing homes, hospitals etc.

As well as disinfecting cooking utensils, eating utensils and medical tools, it could also disinfect through UV light, items that would get damaged with water, like face masks, phones, keys, wallets, letters, etc.